Maximum Pallet Size : 44” x 48”

Maximum Weight per Pallet : 3,000 lbs.

Maximum Layers per Pallet : 3

Adhering to the above conditions will ensure compliance with Federal DOT safety regulations.

Please assist the driver in complying with all applicable laws.

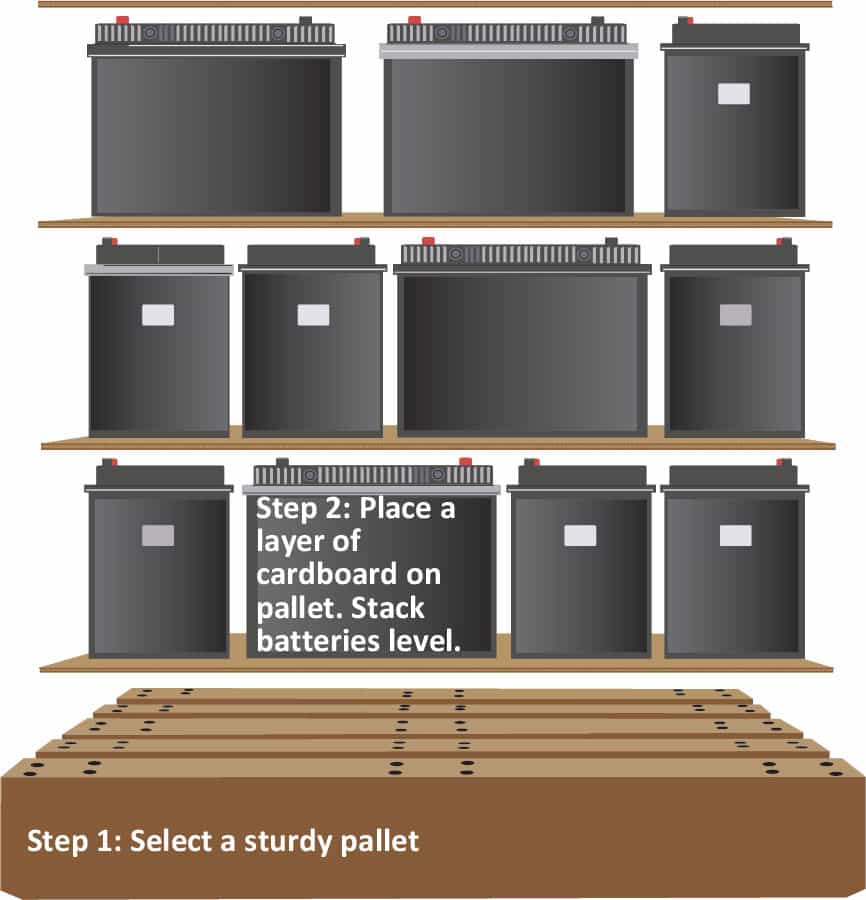

Select a sturdy wooden pallet.

Please note that batteries CANNOT be boxed. All batteries must be placed directly onto the pallet before wrapping and banding.

Place a layer of cardboard on the pallet to ensure that the batteries do not slide off of the pallet.

The first layer of batteries must be level. Shorter batteries should be placed in the center of the layer and taller batteries should be placed on the outside of the layer. The first layer is crucial for the entire pallet to be well balanced and even.

Place an adequate layer of cardboard or honeycomb board between each layer and on the very top of the pallet.

This prevents the possibility of exposed terminals and puncturing the batteries above. It is okay to stack up to 3 levels high.

Secure the batteries to the properly built pallet with shrink wrap after stacking.

Make sure that the wrap connects with the bottom of the pallet as well as with the batteries. If you only wrap the batteries, there is a chance of the load sliding off of the pallet during transport. It is also helpful to use the wrap as a “rope” to pull the batteries toward the center of the pallet (see Figure 1).

Ensure that all outer surfaces are wrapped thoroughly and band the wrapped pallet.

We recommend a minimum of 3 layers of wrap around the entire surface. Figure 3 shows a properly wrapped pallet. A minimum of 3 horizontal bands and 3 vertical bands around the palletized cells is also recommended to prevent the batteries from shifting during transport. Banding should be a minimum of 5/8 inch wide.

Need an NDA? No problem. Your privacy matters to us.

This choice is best for your company if

you need 1-4 pickups per year.

This choice is best for your company if

you need 4+ pickups per year.

Looking to recycle a smaller quantity of batteries? Check out our bucket program